Picking The Right (Or Wrong) Pick And Place Machine

click::1756

Publication time:2024-04-09

The need

Back in August 2018, we got ourselves a desktop pick and place machine from China (there’s a reason why we didn’t talk about this earlier, read on). We wanted to speed up our in-house production that was only equipped with a mighty tweezers. Limited by a small budget and space constraint (plus a door width of 80 cm), we went on to look for one. We knew exactly what we want and here are some of the requirements:

Smallsmt VP-2500D desktop pick and place machine

Main board went kaput – The very moment we installed the vibration feeder that comes with the machine, it started to make a loud noise and that is when we knew something was not right. It turns out that the driver of the vibration feeder located on the main board is damaged and is driving the motor on the vibration feeder well beyond it’s maximum rating. SmallSMT told us it was due to the short circuit caused by the vibration feeder metallic body. We find this rather absurd because there was isolation between the vibration feeder electronics and the chassis of the pick and place machine. Anyhow, they sent us a replacement main board albeit it sure looks like a board that has been used before and repaired judging from the amount of flux residue from hand soldering on the new main board.

North feeder working inconsistently – A bulk of our time spent on the machine was on configuring the push feeder. It is at best described as “fiddly” and “inconsistent”. It would work perfectly during the setup process, but would then fail to accurately advance the tape of reels during normal operation. This resulted in countless halted job anytime in a pick and place job. But, what baffled us was why it would run almost perfectly on the west feeder but not on the north feeder? We tried every tricks and method suggested by SmallSMT but most of the time it would work fine for a short while before going back to it’s old self. We desperately need the north feeder because there is where our components that comes in 12 mm, 16 mm and 24 mm tape width reels can be installed. Even more shocking, SmallSMT told us the 24 mm feeder is actually not supported! Why sold it to us at the first place?

Reel cover tape snapping way too often – The machine uses a push feeder (instead of a drag feeder) to advance the component reels. A mechanical cover tape peeling mechanism will pull the cover tape towards the back to expose the component to the pick and place head. How tight or lose the tension on the cover tape can be adjusted to one of the 3 settings on the machine. However, even at the least tight setting, the cover tape on our component reels snap way too often. Again, this resulted in countless stop on the pick and place job.

Some feeder pick up locations are not reachable by the top camera – In order to configure the pick up location, we need to move the head manually to the pick up location without vision assistant. This process needs trial & error and we spent a lot of time here. The vibration feeder is one of the location not accessible by the camera on top of few other push feeders.

North feeder location not accessible by the head – this is one of the most shocking issue we faced on the machine. When we try to move the head to any of the 8 mm tape width feeder on the north side, the software will complain it is not reachable. A solution given by SmallSMT was to shave off a portion of the y-axis limit end stop. We reluctantly shaved off 2 mm from the y-axis limit end stop metal piece. Even though this solved the problem, we start asking our self, isn’t the machine calibrated and tested at the factory to detect such issues? Or it was not even calibrated? After the fix, the top camera will no longer park at the machine origin (indicated by a engraved mark on the machine bed) when the homing function is executed. An offset of 2 mm was also needed on the software to tell the machine everything has been moved by 2 mm on the y-axis.

Removable feeders – it is our mistakes on our first purchase to think assume that fixed feeders are easily manageable and reels can be swapped in and out without much trouble. Oh boy, we were so wrong.

Industry proven removable feeders – removable feeders are expensive, full stop. The total cost of the feeders alone could easily equal that of the machine cost. By having machine with industry proven feeder, we will not be locked down held ransom to a propriety feeder made by the machine manufacturer. This bring us to the tested and proven pneumatic Yamaha CL feeder that were used on the Yamaha YV and YG series machine. There are still abundance of these machine available in the 2nd hand market and they are built like a tank. A lot of newer machine from China uses these Yamaha CL feeder due to it’s reliability, robustness and cost. If you dig deep and spend some time looking, Yamaha Cl feeder can be had as low as USD40 for variant supporting 8 mm tape width. In the 2nd hand market, we found some retailing at USD15. Obviously, these feeder even brand new ones are no longer original feeder made by Yamaha but clones. However, due to it’s simplicity (at least in the feeder design world), they are copied to perfection.

As many head as possible – we figured out that having an automatic nozzle changer is a very cool feature but it also introduces another problem (at least on our previous machine). Whenever a nozzle is being changed, this introduce some amount of error and deviation due to the fitting of the nozzle to the head. 4 heads is minimum and 6 & 8 heads is widely available for larger machine. Based on our BOM of various designs, having 4 different nozzle is enough to complete a pick and place job without changing the nozzle.

Conveyor belt – we think this is a very convenient mechanism to load the PCB onto the machine. Having to place the PCB to a fixture manually is really time consuming. Furthermore, if we decided to expand our manufacturing lines, we can cascade several machine in the same line or add automatic stencil printer with reflow oven that comes with conveyor belt too. This is not possible if the conveyor belt feature is not available.

Widely used by factories and not some Youtuber – this is one of the mistake we made and this is one of the reason (if not the most important reason) on which machine we ended up with the 2nd time around. As we dig deep into the small scale PCBA manufacturing in China, we do notice many of these factories are either using 2nd hand machine like those older Yamaha (YV/YG), Juki, Samsung, etc machines or brand new made and designed in China machine. Due to the space issues, we obviously cannot fit a big machine like those 2nd hand machine. While those brand new made in China machine comes in variety sizes and specifications.

As many feeder as possible – no feeder is too much.

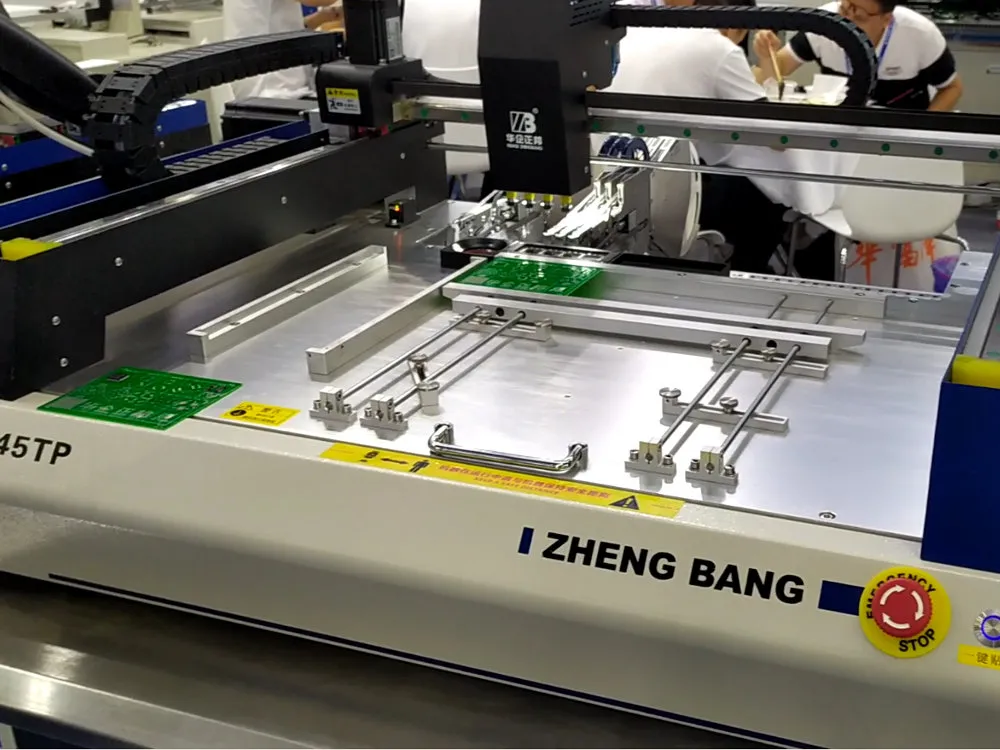

| Specifications | Wenzou ZhengBang | Kayo | Boreytech | Huawei Guochang |

| Model | ZB3545TP | A4 | SMT-W1-F | HW-T4SG-50F |

| Mounting heads | 4 | 4 | 6 | 4 |

| Feeders | 38 | 46 | 52 | 50 |

| Motion drive system | Belt | Ball screw | Ball screw | Ball screw |

| Camera | 5 + 1 | 5 + 1 | 1* + 1 | 5 + 1 |

| PC | Built-in | External | External | Built-in |

| Smallest component size | 0402 | 0402 | 0402 | 0201 |

| Largest component size | 22 mm x 22 mm | 40 mm x 40 mm | 25 mm x 25 mm | 40 mm x 40 mm |

| Minimum component pitch | 0.5 mm | 0.3 mm | 0.5 mm | 0.3 mm |

| Maximum z-axis movement height | 12 mm | 20 mm | 15 mm | 20 mm |

| Weight | 120 kg | 240 kg | 200 kg | 210 kg |

| Price (FOB) | $6000 | $7500 | $7600 | $6580 |

| Optional electrical port | – | – | – | $350 |

* flyby vision camera

** using optional electrical feeder

*** maybe over specked advertised

**** FOB destination (to Malaysia) supplied by Glichn (HWGC reseller for export market)

A trip or two to China

As we are based in Malaysia in the center of South East Asia, we are spoiled with cheap flights to China. This allows us to go on short trips lasting 2-4 days for few hundred dollar. We went to Shenzhen, China back in August 2019 and another trip to Beijing, China back in December 2019 (yes! when CoVid-19 was still not considered a worldwide threat).

Shenzhen August 2019

A super short trip of 2 days 1 night jammed packed with machines to evaluate. The trip basically consist of 2 parts spread across 2 days:

Shenzhen NEPCON 2019

There are other similar sized companies like Charmhigh at the exhibition offering similar sized machine but before the trip, we did ask them on whether they would release any new machine or any upgrade plans on their existing benchtop machine like the CHMT560P4 which has 60 feeders capacity. The answer is pretty straight forward in which they said they are concentrating on larger machine and benchtop machine are no longer a priority. That is when we decided to skip putting any effort on checking out their machine. But their new CHM-861 flagship monster machine sure looks promising.

The regular big player was present at the exhibition like Yamaha, Juki and Autotronik just to name a few. But, their offering is beyond our budget and dimension requirements. We left the exhibition before the sun sets in a disappointing manner. But, in a way we managed to cross out one of the machine candidate out of the list. We ended the day with a warm bowl of dumpling before hitting the sack after a long day (we traveled from midnight the day before!).

Wenzhou Yingxing Technology Huawei Guochang Shenzhen factory visit

We basically bought:

We reached Beijing on a cold sub zero morning that was so uncomfortable for someone that lives under the hot sun 365 days in a year. Alas, after dropping off our already light backpacks at our Airbnb, we jumped onto the subway and traveled as far as the subway line could bring us to the north of Beijing. At the last station, a sales representative name Ms Karen Peng and her colleague from Beijing Glichn picked us up to the HWGC factory. We were greeted by the engineers at the HWGC factory that were suit up with their company yellow and black windbreaker (wondering why they didn’t paint their machine in that color which would be very cool) and a stash of yet to be assembled machine frame/body.

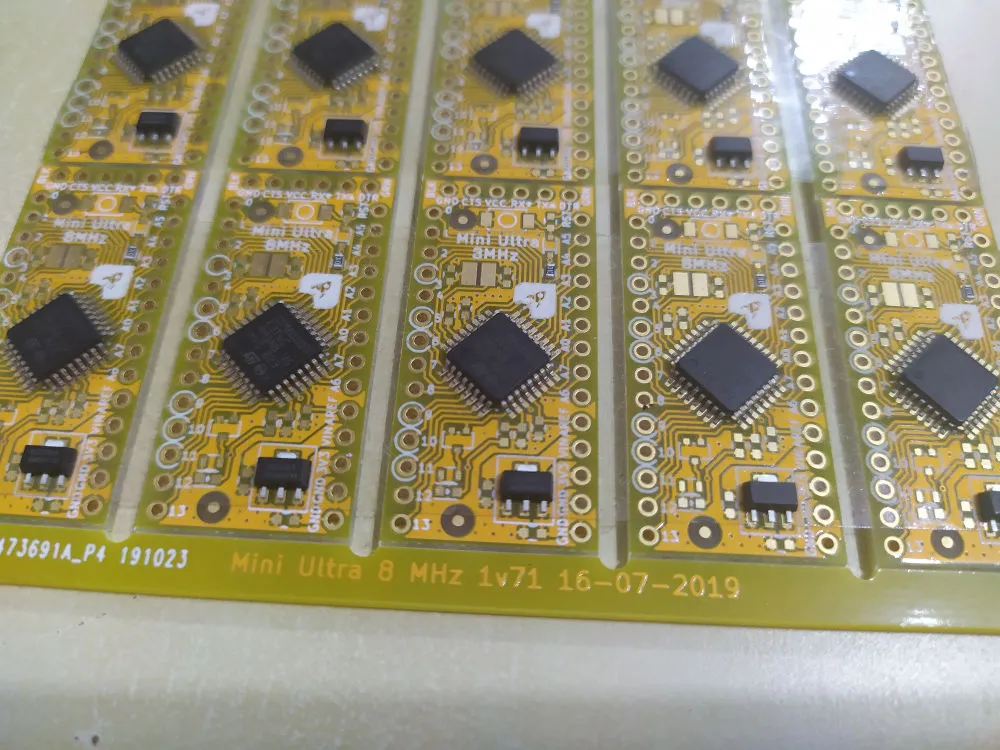

They have prepared a machine to test out our PCB. We also noticed that all our components purchased from Taobao has arrived safely on the premise prior to our visit. The engineer took about 15 minutes to set up our PCB and did a trial run of mounting process. We managed to observe on the flow of work to use the machine. Although we brought our PCB pick and place file with us, the engineer decided to do it manually by specifying the coordinate of the components on a single PCB and multiplying them across the entire panel. It’s amazing how fast he can do it without much fuss.

We did a few runs of the pick and place process (we should have brought more copies of PCB, we ended removing the components from the double sided tape after each run!) and here’s an example of the accuracy. We can say they are mostly spot on, but the direct use of the PCB pick and place file would probably produce an even more accurate result. Again, it’s pretty much mirrored what we have seen at their Shenzhen office on the larger machines.

One important feature that we think could be useful for us in the future is the ability of the machine to use electrical feeder. They claimed their machine can pick and place components down to the size of 0201 using their electrical feeder.

After spending about more than an hour, we decided to make a move as we can see everyone is so busy doing something. It’s best to let them to continue on their work. Before we leave, they showed us around their factory. Never in our life, we saw so many pick and place machines!

Epilogue

Unfortunately, then came the whole Covid-19 virus pandemic that affects the entire world. We were lucky we came back safely as early as in December 2019, it was reported that the virus was already in its initial stage of spread in China. China went into lock down mode as well as here in Malaysia shortly after that. Everything came to a halt and the future became unclear. Buying a machine would be a big risk and we were holding our wallet tight. Companies downsizing and closing down, people losing their jobs, industries lost its importance and lives are lost more importantly. We decided to put our machine on hold. We would also like to thank our customers, especially those that have been buying from us since ages, that kept us going. Only in late June 2020, we placed an order for a unit of HW-T4SG-50F/GP400. We can’t wait for the machine to arrive and it will be shipped by slow boat to reduce the cost of shipping for something that weighed almost 260 kg. In our next article, we will be writing about our new machine and maybe some videos on the machine, stay tuned!

As always, take care and stay safe!